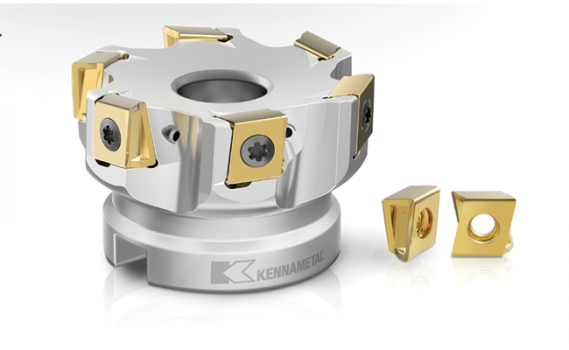

Shoulder Mill Provides Exceptional Strength

Description

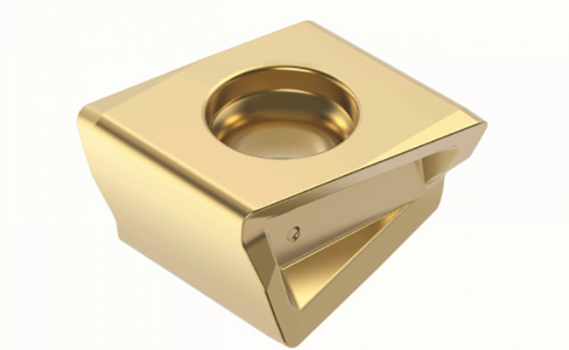

Mill 4-12KT, the next generation of tangential shoulder milling, features a triangular-shaped margin design providing cutting edges with exceptional strength to produce high-quality floor surface finishes for nearly all steel and cast iron applications.

The mill has tangentially mounted inserts with four cutting edges per insert for reduced tooling costs. Seven corner radii from 0.016 to 0.122 in. are available, along with coolant-through, medium and coarse pitch cutter bodies 2 to 8 in. in diameter. With an axial depth of cut range from 0.019 to 0.472 in., Mill 4-12KT covers most shoulder milling applications.

Multiple factors contribute to significant performance increases, even in aggressive cutting conditions:

- The tangential, "on-edge" insert design allows the insert to take advantage of the strength of the carbide thickness more so than radially mounted inserts found on traditional milling cutters.

- A shallow pocket design, allows the core size of the cutter body to be very robust.

- The axial and radial seating surface designs provide exceptional stability.

Specs

Features:

- Patented margin design ensures unprecedented stability.

- Tangentially mounted inserts give easy access to insert locking screws.

- Coarse and medium pitch cutters with internal coolant supply.

- Strong cutter body and strong cutting edges due to tangential design concept.